The cost of air conditioning repair depends on several factors. A basic service fee covers the technician’s time to come out and diagnose the problem. Parts and labor vary by location.

If your AC unit isn’t running, check to make sure a breaker hasn’t been tripped. Then, follow these tips to troubleshoot and fix the issue.

Evaporator Coil Cleaning

Coils are one of the most important parts of your air conditioner, and keeping them clean is key to maximizing efficiency. Dirty coils can cause a variety of problems, from increasing system wear to causing the compressor to overheat and shut down. Fortunately, cleaning coils is relatively easy, and it’s usually included as part of a routine maintenance appointment.

During this process, your service technician will usually start by blowing an air compressor into the coils in a direction opposite of the normal flow to get small debris and dust out. Then, they’ll use a shop-style vacuum (be sure to wear protective eyewear!) to get the rest of the dust and dirt. Finally, they’ll spray a thick coat of cleaner on the coils and fins, following any instructions that are listed on the product they’re using.

It’s also a good idea to run a fin comb or brush (available at most hardware stores and AC shops) along the fins to straighten any that have become bent or crushed. This will help them get a better fit and improve the airflow through the coil, making your system more efficient.

Compressor Coil Cleaning

Cleaning the compressor coils is an essential part of an air conditioning repair. The dirt buildup can block airflow and cause the system to work harder than it should, which shortens its lifespan and increases your energy bill. Dirty coils can also lead to mold and mildew growth that may discolor the walls or carpet of your home.

To clean the coils, the dealer will first turn off power to the AC unit and remove the access panel to expose the evaporator coil. Then the dealer will blow away loose dirt and debris with a shop vac or an air compressor canister. He or she will also straighten the aluminum fins of the coil if they are bent. This is a delicate job and shouldn’t be done too quickly or vigorously to avoid damaging the fins, which are very thin metal.

After sweeping and vacuuming the area around the coil, your dealer will apply a thick coat of cleaner across the coils and fins, following any instructions listed on the product. He or she will let the solution sit for five to 10 minutes to allow the heavier buildup to break down and then wipe down the coils again with a cloth or brush.

Be sure to use a non-acidic cleaner, as acidic cleaners can damage copper and alloy metals used in the coil. Then the dealer will rinse the coils with water if the cleanser’s label indicates that it must be rinsed off.

Coolant Lines

Coolant lines are insulated copper lines that transport refrigerant between the air conditioner unit outside your home and the evaporator coil inside your home. There are two different types of coolant lines: one carries a gas and the other carries a liquid.

Over time, outdoor elements and the natural aging process can take their toll on these copper lines causing them to leak small amounts of refrigerant. When this happens, the coolant cannot move through the system properly, and the evaporator coil becomes excessively cold. This causes the cold refrigerant to change from a gas to a cold liquid, which can then freeze the line and coil.

If you notice a frozen AC line, turn off the unit and put it on fan mode. The next step is to find out what is causing the problem.

If the coolant is low, it will need to be recharged. However, a professional will always look for and repair the source of the leak before refilling the system with coolant. This will prevent the leaking coolant from being sucked into a faulty part in the compressor and eventually lost to the environment. This is what many less-than-honest companies do to try and make additional money. A Progressive Air Systems technician will never do this. They will only replace the coolant after fixing the leaky hoses.

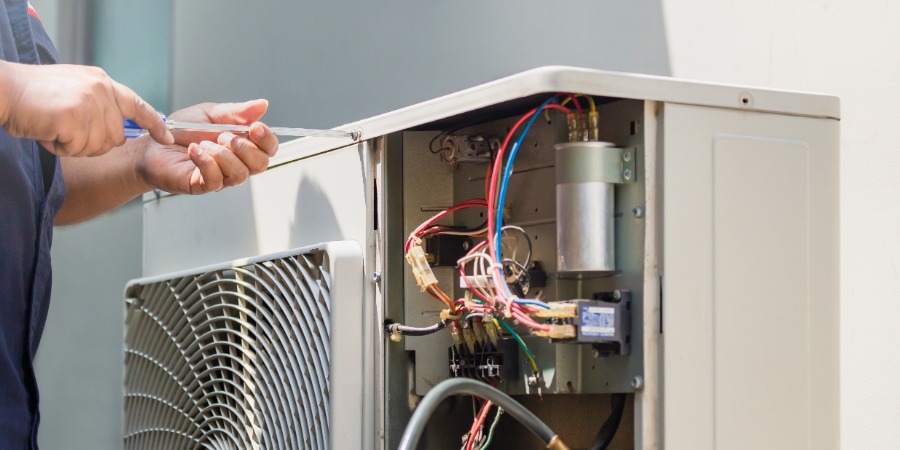

Electrical Issues

There are several electrical issues that can occur with AC repair. One is a tripped circuit breaker. In most cases, this can be easily remedied by resetting the breaker and waiting a few minutes before turning it back on. If this is a recurring issue, it’s likely time to replace a fuse or even the whole circuit breaker. This is a task that should be left to a professional electrician with experience working on HVAC systems and electrical panels.

Capacitors can also fail. Over time capacitors will degrade and stop providing enough startup power to start the compressor and fan motor. To help extend their life, it’s a good idea to replace them about every five years. To do so, first shut off the system and then remove the panel from the condenser. This will allow you to see the capacitor, a cylinder-shaped part with 2 or 3 wires on it. To make sure you’re replacing the correct part, take a photo of the old capacitor or write down its number (it’s usually written in MFD – microfarads). You’ll need to use needle-nose pliers to remove the wires and then snap them onto the corresponding tab on the new capacitor.

Electrical wires often have an insulated casing that protects them from damage like corrosion or fraying. If the case has been damaged, it’s a good idea to wrap the affected wires with electrical tape, which will keep them from failing prematurely.